Granite production line is the crushing production line for hard rock which is developed by SANME, we can provide the solution design of granite production line at 30-800tph for customers.

Applicable material

It is suitable for primary, secondary and fine crushing of hard rock materials, such as basalt, granite, orthoclase, gabbro, diabase, diorite, peridotite, andesite, rhyolite, etc.

Application

It is suitable for application in hydropower, highway and urban construction, etc. the particle size can be combined and classified according to the different requirements of customers.

Equipments

Vibrating feeder, jaw crusher, hydraulic cone crusher, vibrating screen, belt conveyor.

Introduction of Hard rock

Hard rock refers that under saturated humidity the uniaxial compressive strength of rock sample is more than 29.4×103kPa(diameter of the sample is 7~10CM, height is the same as diameter ) (magmatic rock such as granite, diorite, basalt; sedimentary rock such as calcareous ferruginous cemented conglomerate, sandstone, limestone, argillaceous limestone, dolomite; metamorphic rock such as gneiss, quartzite, marble, slate ), and has a high abrasiveness to abrasion resistant parts, therefore the hard rock production line should be designed properly, which not only consider the investment cost of crushing project, but also consider the operation cost.

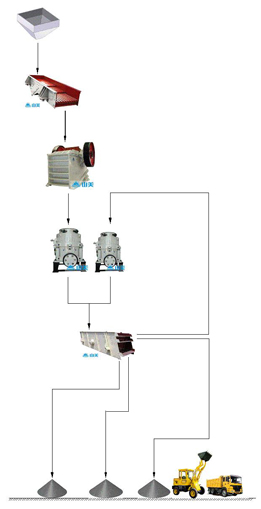

Basic process of hard rock production line

Rock material is conveyed by vibrating feeder to jaw crusher for primary crushing, the crushed rock is conveyed by belt conveyor to cone crusher for further crushing; secondary crushed rock is conveyed by belt conveyor to vibrating screen for screening, rock with qualified particle size is conveyed by belt conveyor to final product; and rock with unqualified particle size is conveyed by belt conveyor to secondary or tertiary cone crusher for crushing again, to form multiple closed circulation. Particle size of final product can be combined and graded according to the requirements of customers.

Performance of hard rock production line

The hard rock production line is highly automated with high crushing rate and low operation cost, it is energy conversation and environmental protection, and has an even and excellent particle size with optimized gradation. The production line is designed according to the hardness of rock and customers’ requirements on particle size, Sanme can provide a complete process solution and technical support for customers according to different production sites, and also can design non-standard parts according to actual installation conditions of customers.

Per: Limestone processing

Next: Steel slag Processing